Views: 0 Author: Chole Publish Time: 2024-07-17 Origin: www.tianchengroup.com

When it comes to designing a motion system, selecting the appropriate motors and drives is crucial for achieving optimal performance. As an experienced engineer at Tianchen Laser, a leading fiber laser cutting machine manufacturer in China, I have gained valuable insights into the impact of motor and drive choices on motion system efficiency. In this blog post, we will explore how these components influence the overall performance of your motion system and provide guidance on making informed decisions.

Motors and drives are the heart of any motion system, working in tandem to convert electrical energy into precise mechanical movement. Motors generate the necessary torque and speed, while drives control and regulate the motor's operation. The selection of these components directly affects the accuracy, speed, smoothness, and reliability of the motion system.

When it comes to choosing motors and drives for your motion system, two prominent brands often come to mind: INOVANCE and YASKAWA. Both companies offer high-quality products, but each has its strengths and considerations.

INOVANCE is a well-established Chinese manufacturer known for its cost-effective solutions. Their motors and drives are designed to deliver reliable performance at competitive prices. INOVANCE offers a wide range of servo motors, stepper motors, and drives that cater to various industrial applications, including fiber laser cutting machines.

Cost-effective solutions without compromising on quality

Wide product range to suit different requirements

Good technical support and after-sales service

Proven track record in the Chinese market

YASKAWA, a Japanese company, is renowned for its high-precision and advanced motion control technologies. Their motors and drives are known for their exceptional accuracy, speed, and reliability. YASKAWA's products are widely used in industries that demand the highest level of performance, such as robotics, semiconductor manufacturing, and high-end machine tools.

Superior precision and accuracy

Advanced motion control features

Robust and reliable performance

Global presence and support network

When selecting motors and drives for your motion system, several key factors should be taken into account to ensure optimal performance:

Application Requirements: Consider the specific demands of your application, such as speed, torque, accuracy, and load capacity. Choose motors and drives that can meet or exceed these requirements.

Compatibility: Ensure that the selected motors and drives are compatible with each other and with the rest of the motion system components, such as controllers and feedback devices.

Power and Voltage Ratings: Match the power and voltage ratings of the motors and drives to the requirements of your application. Proper sizing is essential for efficient operation and longevity.

Feedback and Control: Determine the type of feedback (encoder, resolver, etc.) and control (position, velocity, torque) needed for your application. Select motors and drives that support the required feedback and control methods.

Environment and Mounting: Consider the operating environment and mounting requirements of your motion system. Choose motors and drives that can withstand the expected conditions (temperature, humidity, vibration, etc.) and have suitable mounting options.

Cost and Budget: Evaluate the cost of the motors and drives in relation to your budget and the overall system cost. Strike a balance between performance and affordability while ensuring long-term reliability and efficiency.

Once you have selected the appropriate motors and drives, there are several strategies to optimize the performance of your motion system:

Proper Tuning: Fine-tune the motor and drive parameters to achieve the desired motion profile, response time, and stability. Utilize advanced tuning techniques, such as auto-tuning or model-based tuning, to simplify the process.

Efficient Power Transmission: Minimize power losses by using high-quality cabling, proper grounding, and shielding techniques. Ensure that the power transmission components are properly sized and rated for the application.

Effective Cooling: Implement adequate cooling measures to dissipate heat generated by the motors and drives. Proper cooling helps maintain optimal performance, prevents overheating, and extends the lifespan of the components.

Regular Maintenance: Establish a regular maintenance schedule to keep the motors and drives in top condition. This includes periodic inspections, cleaning, lubrication, and replacement of worn or damaged parts.

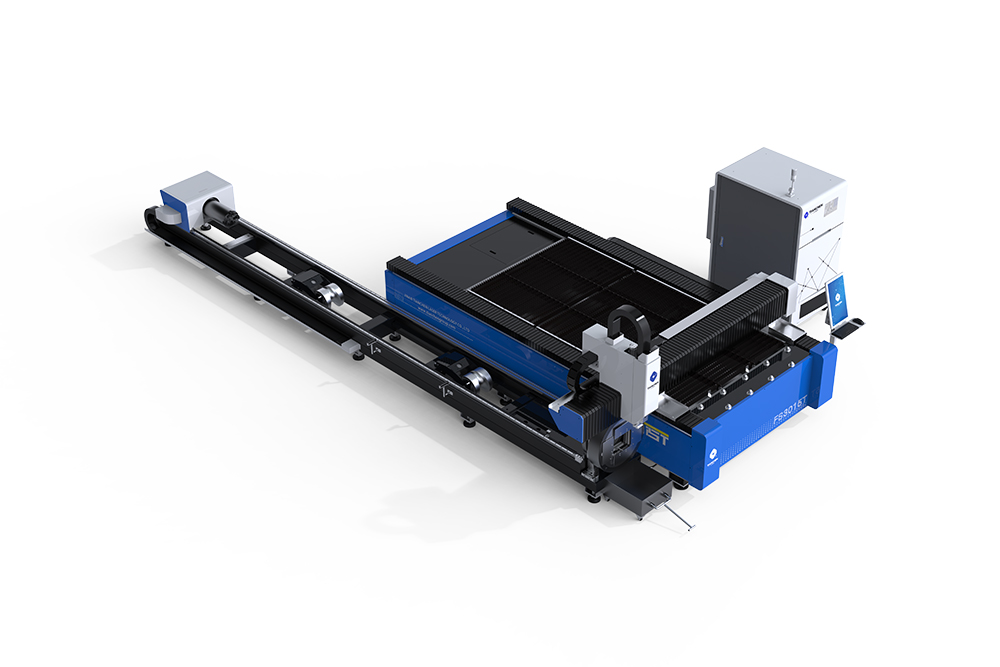

At Tianchen Laser, we specialize in providing state-of-the-art fiber laser cutting machines for industrial applications. Our machines are equipped with carefully selected motors and drives that deliver exceptional performance, precision, and reliability.

As a leading manufacturer in China, we understand the importance of choosing the right components for your motion system. Our team of experienced engineers can guide you in selecting the most suitable motors and drives based on your specific requirements and budget.

Whether you opt for INOVANCE or YASKAWA motors and drives, or any other reputable brand, we ensure seamless integration and optimization of these components within our fiber laser cutting machines. Our machines are designed to handle large-scale metal cutting tasks with unparalleled accuracy and efficiency.

Choosing the right motors and drives is a critical step in achieving optimal motion system performance. By understanding the role of these components, comparing leading brands like INOVANCE and YASKAWA, and considering key factors such as application requirements, compatibility, and cost, you can make informed decisions that will enhance the efficiency and reliability of your motion system.

At Tianchen Laser, we are committed to providing our customers with the best fiber laser cutting machines that incorporate high-quality motors and drives. Our expertise in the industry, combined with our dedication to customer satisfaction, makes us your trusted partner in delivering high-performance motion systems.

If you're looking to upgrade your motion system or invest in a state-of-the-art fiber laser cutting machine, look no further than Tianchen Laser. Contact us today to discuss your requirements and discover how we can help you achieve optimal performance in your industrial cutting applications.

Key Features and Capabilities of Tianchen Laser's Flatbed Laser Cutting Machines

Enclosed vs. Open-Bed Fiber Laser Cutters: Understanding the Key Differences

What materials can be efficiently cut using an enclosed fiber laser cutting machine?

What are the crucial factors to consider when selecting an enclosed fiber laser cutting machine?

Metal Tube Laser Cutting vs Traditional Methods: A Comprehensive Comparison

Mastering Material Selection for Metal Tube Laser Cutting: Tips and Best Practices

Mastering Your Fiber Laser Cutting Machine: A Step-by-Step Guide

Fiber Laser vs CO2 Cutting: Clear Advantages You Can't Ignore

6 Transformative Benefits of Integrating Fiber Laser Cutting into Your Manufacturing Process