Views: 0 Author: Chole Publish Time: 2024-06-27 Origin: www.tianchengroup.com

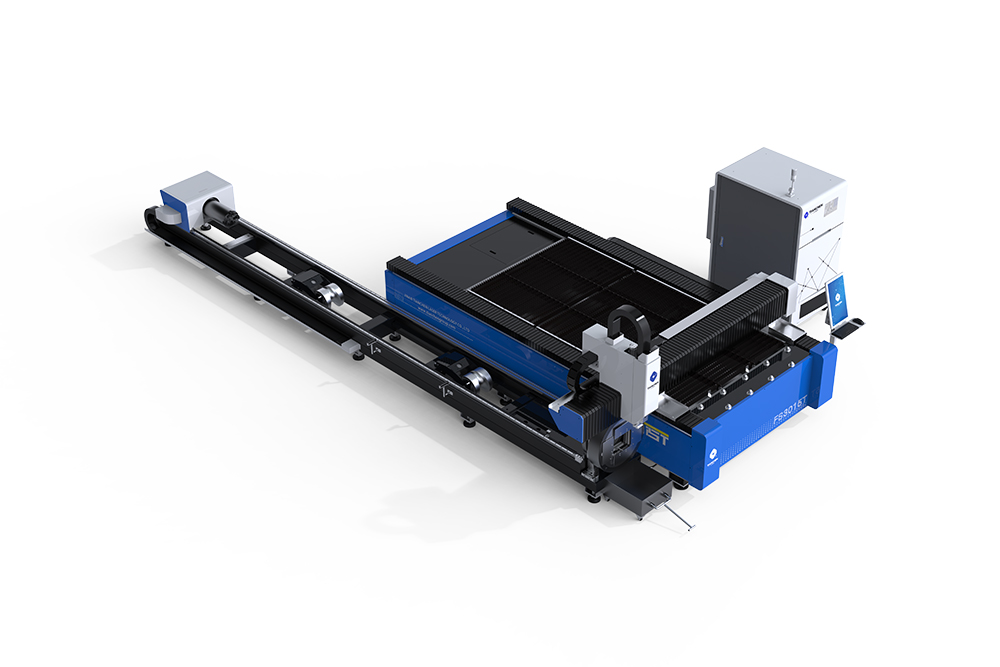

Fiber laser cutters have become an indispensable tool in the metalworking industry, especially for processing metal tubes and sheets. Tianchen Laser, with the expertise of engineer Chloe, is a leading provider of these advanced machines in China. Chloe's extensive experience in fiber laser cutting technology ensures that the information provided here is both reliable and professional. This article delves into the key advantages of using fiber laser cutters for processing metal tubes and sheets, highlighting why they are the preferred choice for many industrial applications.

One of the most notable advantages of fiber laser cutters is their superior precision and accuracy, which is critical for industries that require exact specifications.

Fiber lasers produce a high-quality beam with a small spot size, resulting in precise cuts. This high beam quality is achieved through the use of fiber optics, which provide a more focused and stable laser beam compared to traditional CO2 lasers.

Small Spot Size: The small spot size allows for fine and detailed cuts, essential for intricate designs and patterns.

Stable Beam: The stability of the beam ensures consistent performance, reducing errors and improving overall quality.

Tianchen's fiber laser cutters are equipped with advanced positioning systems that enhance accuracy.

Servo Motors: High-precision servo motors control the movement of the cutting head, ensuring accurate positioning.

CNC Control Systems: Computer Numerical Control (CNC) systems provide precise control over cutting parameters, allowing for repeatable and reliable cuts.

Fiber laser technology significantly increases cutting speed, making the manufacturing process more efficient and productive.

Fiber lasers offer high power output, enabling faster cutting speeds even on thicker materials.

Power Ranges: Tianchen's machines come with various power options, from 500W to over 10kW, catering to different cutting needs.

Thick Material Cutting: High power output allows for efficient cutting of thick metal sheets and tubes, reducing production time.

The cutting algorithms used in Tianchen's machines are optimized for speed and efficiency.

Path Optimization: The software optimizes the cutting path, minimizing travel time and increasing cutting speed.

Piercing Techniques: Advanced piercing techniques reduce the time required to start cuts, further enhancing speed.

Fiber laser technology provides versatility in handling various metallic materials, making it suitable for diverse applications.

Tianchen's fiber laser cutters can handle a wide range of metals, including:

Stainless Steel: Ideal for applications requiring corrosion resistance and strength.

Aluminum: Suitable for lightweight and high-strength applications.

Copper and Brass: Perfect for electrical and decorative applications.

Adaptive cutting technology adjusts cutting parameters based on the material being cut, ensuring optimal performance.

Automatic Parameter Adjustment: The machine automatically adjusts laser power, speed, and focus based on the material type and thickness.

Material Database: A comprehensive material database allows for quick and easy setup, reducing downtime.

Energy efficiency is a critical consideration for modern manufacturing, and fiber laser technology excels in this area.

Fiber lasers are more energy-efficient than traditional CO2 lasers, consuming less power while delivering high performance.

Efficient Light Conversion: Fiber lasers convert electrical energy into laser light more efficiently, reducing energy consumption.

Reduced Cooling Requirements: The compact design of fiber lasers reduces the need for extensive cooling systems, further saving energy.

The eco-friendly design of Tianchen's machines contributes to sustainable manufacturing practices.

Reduced Carbon Footprint: Lower energy consumption results in a reduced carbon footprint.

Recyclable Components: The use of recyclable materials in the machine's construction minimizes environmental impact.

Safety is a top priority in industrial settings, and Tianchen's fiber laser cutters incorporate several safety features to protect operators and equipment.

The cutting area is fully enclosed, preventing accidental exposure to the laser beam. (Some models)

Protective Enclosure: The enclosure shields operators from the laser beam and flying debris.

Safety Interlocks: Safety interlocks prevent the machine from operating if the enclosure is open.

The machines have automatic shutdown features in case of anomalies, ensuring safe operation.

Error Detection: The system detects errors and shuts down the machine to prevent damage and injury.

Emergency Stop: An emergency stop button allows operators to quickly halt the machine in case of an emergency.

Tianchen's fiber laser cutters are designed for easy maintenance and have a long lifespan, providing an excellent return on investment.

The modular design allows for easy replacement of parts and minimal maintenance.

Quick-Change Components: Key components can be easily replaced without extensive downtime.

Maintenance Alerts: The system provides alerts for scheduled maintenance, ensuring timely upkeep.

The use of high-quality, durable components ensures a long operational life.

Robust Construction: The machine's robust construction withstands the rigors of industrial use.

High-Quality Optics: The use of high-quality optics ensures consistent performance over time.

Investing in a fiber laser cutter from Tianchen can be a cost-effective solution for many businesses. The efficiency and versatility of these machines can lead to significant cost savings over time.

The precision of the cuts minimizes material waste, leading to cost savings.

Accurate Cuts: Precise cutting reduces the amount of scrap material.

Optimized Nesting: Advanced nesting software optimizes the layout of parts on the material, maximizing usage.

Fiber lasers are designed to be energy-efficient, reducing operational costs.

Energy Savings: Lower power consumption translates to reduced energy bills.

Minimal Consumables: Fiber lasers require fewer consumables compared to CO2 lasers, reducing ongoing costs.

Fiber laser technology offers numerous advantages for processing metal tubes and sheets, making it an ideal choice for various industrial applications. Tianchen Laser, with its cutting-edge technology and the expertise of engineer Chloe, provides top-of-the-line fiber laser cutters that deliver superior precision, speed, versatility, and energy efficiency. These machines are designed with enhanced safety features, easy maintenance, and a long lifespan, ensuring a high return on investment.

Tianchen Laser is committed to providing innovative solutions that meet the evolving needs of the metalworking industry. For more information on how fiber laser cutters can benefit your business, contact Tianchen Laser today. Let our team of experts help you find the perfect solution for your cutting needs.

Key Features and Capabilities of Tianchen Laser's Flatbed Laser Cutting Machines

Enclosed vs. Open-Bed Fiber Laser Cutters: Understanding the Key Differences

What materials can be efficiently cut using an enclosed fiber laser cutting machine?

What are the crucial factors to consider when selecting an enclosed fiber laser cutting machine?

Metal Tube Laser Cutting vs Traditional Methods: A Comprehensive Comparison

Mastering Material Selection for Metal Tube Laser Cutting: Tips and Best Practices

Mastering Your Fiber Laser Cutting Machine: A Step-by-Step Guide

Fiber Laser vs CO2 Cutting: Clear Advantages You Can't Ignore

6 Transformative Benefits of Integrating Fiber Laser Cutting into Your Manufacturing Process